- +919974121050 / +91 8460900555

- Info.mscindia@asia.com

ISO 9001:2015 | PED 97/23/EC | AD 2000-Merkblatt W0

ISO 9001:2015 | PED 97/23/EC | AD 2000-Merkblatt W0

We having a In-house pattern shop with full time pattern maker. We having a also certified and qualified patternmakers for more work.

Machines : 1nos of lathes, Drill machine and all instruments for wood and aluminum work.

Benefits : High production patterns will be mounted on match plate for manufacture quality assured castings.

We are doing molding process by two types of method.

1. Co2 Moulding System.

2. No-Back Moulding System (Only For Core In Critical Space)

Sand Moulding :

Manually Molding line for Co2 molding process.

Single piece casting : 20 Kg to 600Kg single piece.

Bed size : 150 X 150 X 150 mm To 1300 X 1300 X 1300mm.

Process time : 12 to 24 hours.

Production : Castings in huge quantities.

We having a two giant induction type furnace of 500 kg and 750 kg with 200 kg, 500 kg & 800 kg ladle. Metal is poured by both the way manual & Crane.

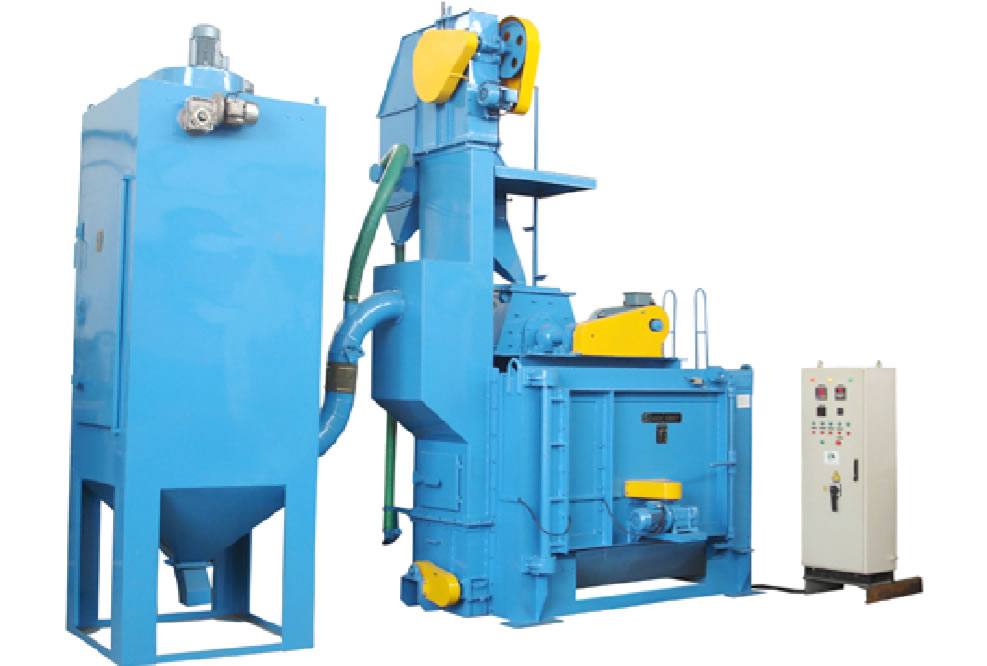

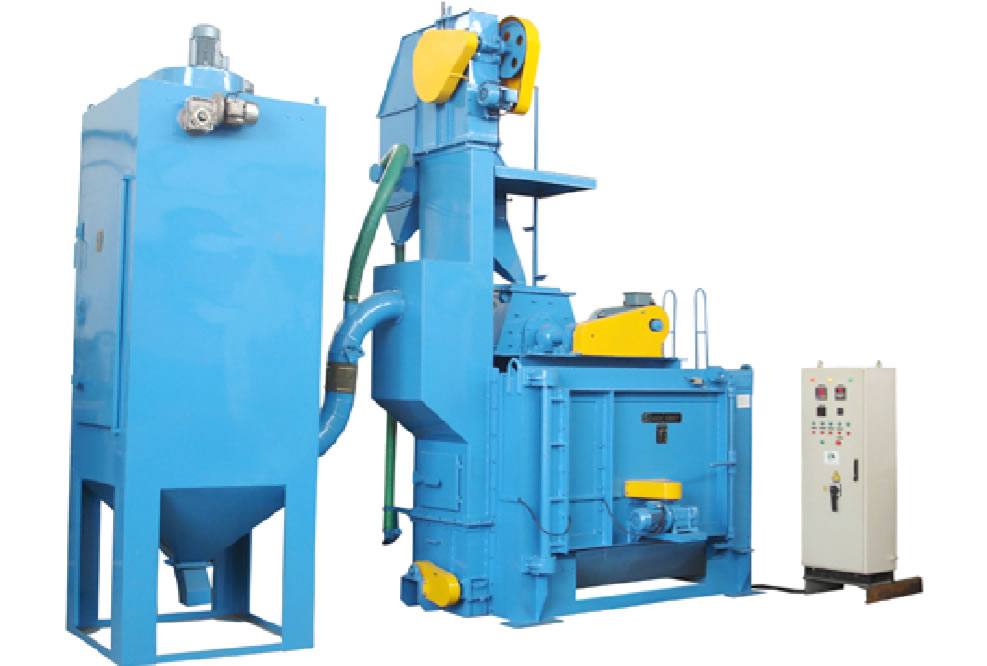

Then the casting under goes to fettling and finishing process such as a gate cutting, Grinding, Sand Blasting, Shot blasting, Acid Pickling, Etc. we having many machinery for this process like Four Numbers Of Breakers for clean the inner side stacked sand from the castings , Three Numbers Of Oxy Flame Cutting, One Numbers Of Arc Cutting and Gouging Machine, Three Numbers Of Arc Welding Machines, Gas Cutting Facilities, Grinder Cutter, Swing Grinder, Batch Grinders, One Numbers Of Shot Blasting Machines, Etc. our fettling capacity is more then 100 MT per.

Then the castings undergoes to heat treatment process as per the material specifications, we maintain documents of the heat treatment graphs and cycles. We are doing this process by our reputed and famous vendor of our Rajkot area.

We having 4 feet long and 700 Kg capacity raised thumb blast shot blasting machine for clean up casting surface.

Manthan Steel Cast Copyright 2026 © All rights Reserved.